Injection Mold Release Agent Selection Guide

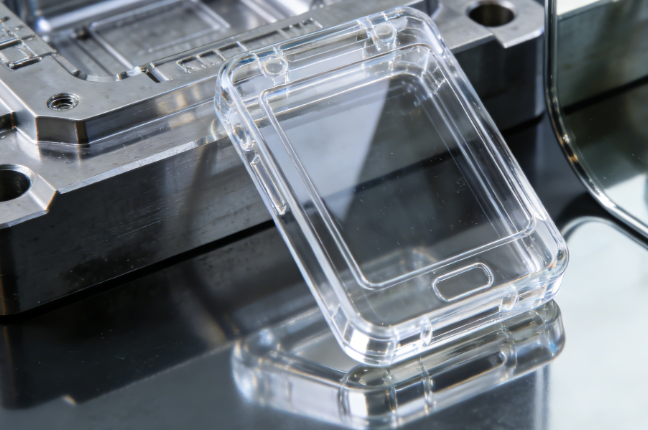

The core function of an injection mold release agent is to create a lubricating barrier between the mold cavity and the part, reducing adhesion and ensuring smooth, defect-free ejection. Selection depends on matching the plastic material, mold characteristics, part requirements, and molding process to avoid surface defects, mold contamination, or reduced productivity.

1. Key Types of Release Agents and Their Properties

1.1 Oil-Based Release Agents

Composition: Mineral oil, paraffin, synthetic esters.

Advantages: Strong release force, low cost, suitable for most general plastics (PE, PP, ABS, PS).

Disadvantages: High residue causes surface hazing or oil stains; volatile fumes at high temperatures.

Best for: Internal structural parts, non-cosmetic components where cost efficiency is prioritized.

1.2 Water-Based Release Agents

Composition: Water-emulsified lubricants and additives.

Advantages: Eco-friendly, low odor, minimal residue, easy to clean.

Disadvantages: Slightly weaker release force than oil-based alternatives.

Best for: Medium-cosmetic parts (home appliance housings, automotive interiors) and materials sensitive to oil contamination (PC, PA).

1.3 Silicone-Based Release Agents

Composition: Silicone oil, silicone resin.

Advantages: Excellent high-temperature resistance (200–300°C), long-lasting effect (multiple releases per application).

Disadvantages: Silicone migration causes surface haze; residue impairs secondary processing (painting, printing).

Best for: High-temperature engineering plastics (PBT, PET, LCP), thick-walled parts, and high-volume production. Strictly avoid for transparent parts (PMMA, PC) or parts requiring secondary finishing.

1.4 Fluorine-Based Release Agents

Composition: Fluorocarbon compounds.

Advantages: Lowest surface tension, superior release performance, high-temperature stability, and no residue impact on secondary processing.

Disadvantages: High cost, precise application required.

Best for: High-precision, high-gloss parts (optical lenses, medical devices, food-contact components) and high-temperature specialty plastics (LCP, PEEK).

2. Core Selection Principles

2.1 Match Plastic Material

Low-adhesion general plastics (PE, PP, HIPS): Prioritize oil-based agents for cost efficiency, or high-concentration water-based agents for eco-friendliness.

Medium/high-adhesion engineering plastics (ABS, PA, PBT): Use water-based or low-silicone agents to balance release force and surface cleanliness.

Transparent/high-gloss plastics (PMMA, PC, PETG): Avoid silicone agents; use fluorine-based or silicone-free water-based agents to preserve clarity and gloss.

Food-contact plastics (PP, PE, PC): Select FDA/GB 4806 compliant water-based or fluorine-based agents to ensure safety.

High-temperature specialty plastics (LCP, PEEK): Use heat-resistant fluorine or silicone agents (>300°C) to prevent thermal decomposition.

2.2 Adapt to Mold Characteristics

Steel molds (P20, H13, S136): Compatible with all agent types. For mirror-polished S136 molds (transparent parts), use residue-free fluorine or silicone-free water-based agents.

Aluminum molds: Use neutral water-based agents to avoid corrosion; avoid chlorine/sulfur-containing oil-based agents.

Complex molds (deep cavities, narrow gaps): Use long-lasting silicone or fluorine agents to reduce reapplication frequency; spray-type agents ensure uniform coverage.

2.3 Meet Part Requirements and Secondary Processing

Cosmetic parts (appliance housings, automotive exteriors): Use water-based or fluorine-based agents to minimize residue and ensure compatibility with painting/plating.

Precision parts (gears, connectors): Use fluorine-based agents for thin, uniform films that do not affect dimensional accuracy.

Internal structural parts: Cost-effective oil-based agents are sufficient.

2.4 Align with Molding Process

High-temperature processes (>250°C): Use heat-resistant fluorine or silicone agents to prevent thermal decomposition.

High-speed, short-cycle production: Use long-lasting silicone or fluorine agents to reduce downtime.

Low-pressure molding: Use low-concentration water-based agents to avoid dimensional fluctuations.

3. Practical Usage Tips

Application: Use spray coating for uniform coverage; apply thinly to avoid excess residue.

Mold Maintenance: Regularly clean mold cavities to remove carbonized residue and maintain surface finish.

Compatibility Testing: Conduct small-scale trials before full production to verify release performance, surface quality, and post-processing compatibility.

Storage: Keep agents sealed in a cool, dry place; use water-based agents promptly after opening to prevent degradation.