Dust Prevention Key Points for Injection Molding of Transparent Plastics

Transparent plastics (e.g., PMMA, PC, PET, PSU) are widely used in high-end fields such as electronic optics, automotive interiors, and medical devices due to their excellent optical properties and moldability. However, their injection molding is extremely sensitive to dust contamination—even tiny particles (0.01mm in diameter) can cause bright spots, stains, or haze on the product surface, damaging appearance consistency and mechanical performance. Therefore, dust prevention must cover the entire process of raw material handling, equipment maintenance, production environment control, personnel operation, and post-processing/storage, forming a closed-loop management system in line with industry standards.

1. Dust Prevention for Raw Material Storage and Pretreatment

Raw material management is the first line of defense against dust, requiring strict control at every step:

Storage control: Keep the storage environment dry and clean (relative humidity ≤60%, temperature 20±5℃) to avoid moisture condensation and dust adsorption. Store raw materials in sealed original packaging, at least 5 meters away from dust sources (e.g., crushing/recycling areas), with stacking height ≤3 layers.

Transportation and unpacking: Use sealed turnover boxes for transportation (no open-air transport) and wipe vehicle compartments with dust-free cloth in advance. Unpack only in a local Class 100 clean bench—wipe packaging with 75% medical alcohol-soaked dust-free cloth, wait 30 seconds for volatilization before opening.

Drying treatment: Dry hygroscopic materials (PC/PMMA) with dust-free hot air dryers (PC: 120-140℃ for 2-4h; PMMA: 80-90℃ for 2-4h). Clean drying hoppers weekly with same-material cleaning compound to avoid carbonization of residual materials.

Recycled material control: Filter recycled materials through three stages (100-mesh, 200-mesh, electrostatic precipitation) to ensure impurity particle size ≤0.1mm. Limit recycled material ratio ≤15%, mix with new materials in sealed mixers, and transfer to dry hoppers immediately after mixing.

2. Cleanliness Control of Equipment and Molds

Residual impurities in equipment/molds are major dust sources, requiring standardized daily cleaning and regular maintenance:

Injection machine cleaning: Wipe hoppers/screws/barrels daily, and deep clean weekly—empty hoppers, run cleaning compound for 3-5 cycles, then purge with oil/water-free compressed air (filtration accuracy ≤0.1μm). Install dust covers on hoppers and ≥120-mesh filters at feed inlets (check daily).

Mold maintenance: Polish mold cavities/runners/gates with S136 steel to Ra ≤0.01μm. Wipe cavities with dust-free non-woven cloth and special cleaner (one-way wiping only) before production. Clean exhaust slots daily and coat molds with 5-10μm anti-static coating (compliant with GB12158-2024).

Auxiliary equipment management: Polish conveyor pipe inner walls (surface resistance ≤1×10?Ω) and clean mold cooling pipes monthly to remove scale.

3. Production Environment Cleanliness Control

Environmental cleanliness is critical, complying with GB50073-2013 (Code for Design of Clean Rooms):

Cleanliness standards: Workshop meets ISO 7 (≤352,000 particles ≥0.5μm/m3); molding areas meet ISO 6 (≤35,200 particles ≥0.5μm/m3). Use G4+F8+H13 three-stage air filtration (replace H13 filters every 6-12 months, test efficiency monthly).

Pressure difference and layout: Maintain positive pressure (clean vs. non-clean area: ≥5Pa; different clean grades: ≥10Pa, test daily). Isolate dust-generating processes (crushing) in sealed zones with pulse bag dust collectors.

Daily maintenance: Use anti-static epoxy floors (flatness error ≤2mm/3m), mop twice daily with anti-static cleaner (clean to non-clean direction). Wipe walls/ceilings weekly (smooth color steel plates with rounded corners) and clean sealed turnover carts daily.

4. Personnel Operation Standardization

Personnel activity is a major dust source, requiring strict dress/access/operation rules:

Dress and access: Operators wear GB12014 anti-static clean suits, GB21148 anti-static shoes, and GB/T22845 anti-static gloves (no jewelry/hair accessories). Pass through air showers (0.45±0.1m/s, ≥15s) before entry. Authorize external personnel only after training and accompaniment.

Operation rules: Avoid direct contact with raw materials/transparent surfaces (use disposable gloves, replace every 2h). Place demolded products in clean boxes immediately and cover hoppers after feeding. Control personnel density ≤3 people/100㎡ and clean work areas after production.

5. Dust Prevention for Post-processing and Storage

Post-processing/storage is the final defense against secondary contamination:

Post-processing: Conduct trimming/polishing/coating in ISO 6 clean benches (replace H13 filters every 6 months). Use alcohol-disinfected dust-free tools and 10,000-mesh abrasives with dust-free coolant for wet polishing (wipe with anhydrous ethanol afterward).

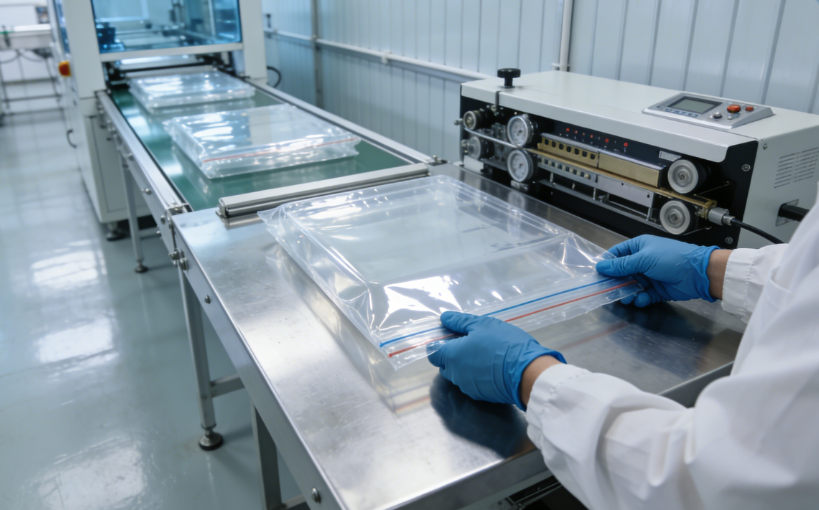

Inspection and packaging: Inspect products in ≥500lux dust-free lighting (5× magnifier). Package qualified products with dust-free cloth-wiped surfaces (packaging pre-stored in clean areas for 24h) using vacuum/anti-static bags (label "Dust/Moisture Proof").

Warehousing and transportation: Store products in warehouses (40-60% RH, 20±5℃) on shelves (≥10cm from ground/walls, wipe weekly). Transport in sealed vehicles (cleaned compartments) with stacking height ≤packaging load limit.

Summary

Dust prevention for transparent plastic injection molding is a systematic project following the principles of "source control, process management, and end protection". Implementing all measures in accordance with industry-recognized standards (temperature, humidity, cleanliness, filtration accuracy) and establishing regular inspections/training ensures stable optical performance and appearance quality of transparent products for high-end applications.