-

ABS Mold Material Selection

ABS (Acrylonitrile-Butadiene-Styrene copolymer) is a widely used engineering plastic in injection molding, valued for its impact resistance, rigidity, corrosion resistance and processability, and appl

2026/01/07 Injection Molds

-

Common Plastic Materials Overview

Plastics, as a widely used synthetic polymer material, have advantages such as light weight, easy processing, and controllable cost, and have permeated into various fields of production and life. Here

2026/01/07 Plastic Materials

-

Solutions to Gloss Defects on ABS Injection-molded Products

Gloss defects—local highlights, uneven reflection or bright spots—are common in ABS injection molding, seriously undermining product aesthetics and market acceptance. Root causes lie in mold condition

2026/01/06 Injection-molded

-

Polishing Methods for Optical Injection Molds

Polishing of optical injection molds is critical, directly determining the micro-topography of mold cavities and thus the light transmittance, imaging accuracy and surface quality of optical parts. Op

2026/01/06 Injection Molds

-

Solutions to Warpage Issues in Injection-molded Products

Warpage is a common quality defect in injection-molded products, characterized by warping, bending and uneven shrinkage after cooling. It directly impairs assembly accuracy and service performance. Ro

2026/01/06 Injection mold

-

How to Improve the Precision of Thin-Wall Injection Molding

In high-end manufacturing sectors like electronics, automotive and medical devices, thin-wall injection molding stands as a core process, valued for lightweight, miniaturized products and high-efficie

2026/01/06 Injection Molding

-

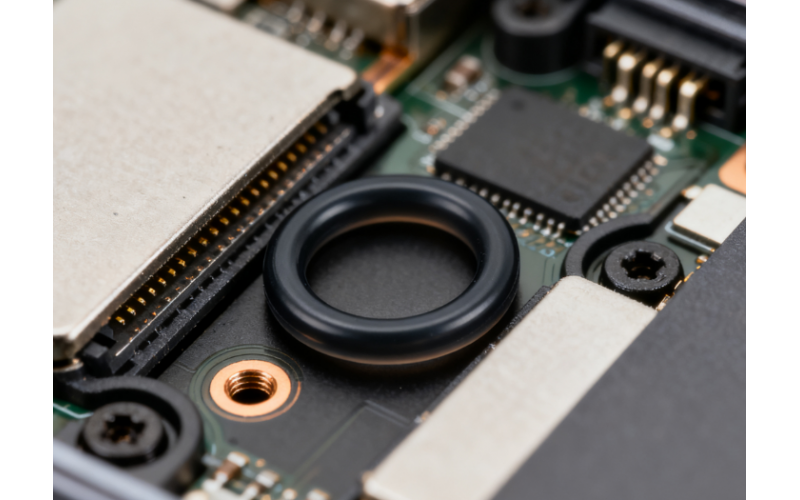

Guide to Common Materials for Sealing Rings and Selection

Sealing rings are core components of industrial sealing systems, and their material properties directly determine sealing reliability, service life and equipment operational safety. Under different wo

2026/01/06 Sealing Rings

-

What kind of steel is used for ABS plastic molds?

ABS materials, with balanced strength, toughness and processability, are widely used in home appliances, automotive and electronics industries. The steel selection for ABS injection molds directly det

2026/01/05 Injection Molds