-

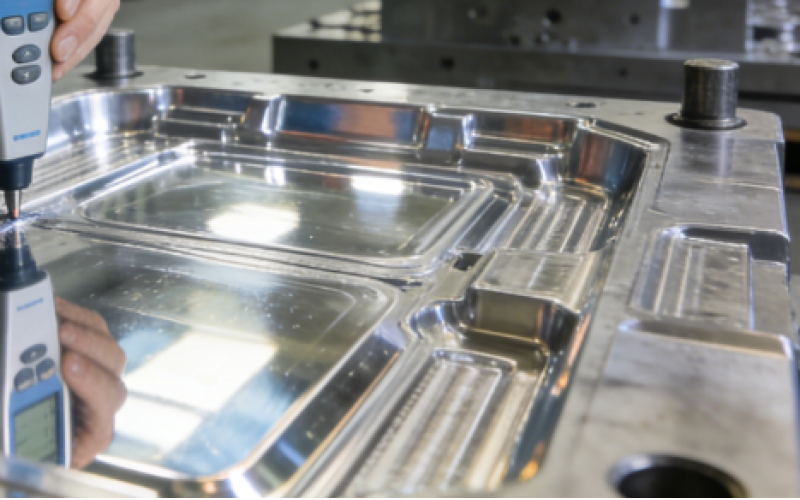

Control of Injection Mold Cavity Polishing Grade

The polishing grade of an injection mold cavity directly determines part surface finish, ejection performance, and mold lifespan. Proper polishing ensures uniform melt flow, reduces mold sticking, and

2026/01/30 Injection Mold

-

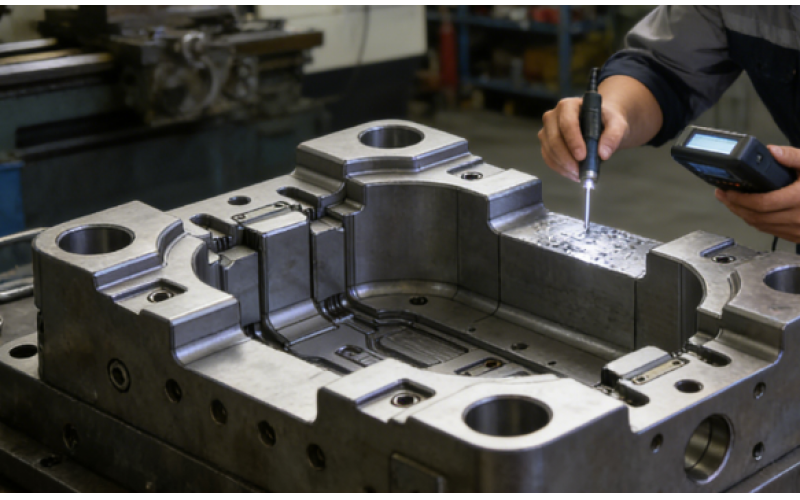

Design Points of Plastic Mold Runner

I. IntroductionThe runner system in plastic molds is the critical channel that delivers melt from the nozzle to the cavity. Its design directly impacts melt flow, filling balance, part quality, and ma

2026/01/30 Plastic Mold

-

Reasonable Setting Method of Back Pressure Parameter in Injection Molding

I. IntroductionBack pressure is a critical plasticizing parameter in injection molding, influencing melt uniformity, gas removal, and production efficiency. Incorrect settings can cause defects like m

2026/01/30 Injection Molding

-

High-Speed Filling Process Debugging for Thin-Wall Injection Molding Parts

I. IntroductionThin-wall injection molding (defined as wall thickness ≤1.5mm and length-to-thickness ratio >100) is critical for producing lightweight, high-efficiency components in electronics, pa

2026/01/30 Injection Molding

-

PE Injection Mold Material

I. IntroductionPolyethylene (PE) is one of the most widely used general-purpose thermoplastics, valued for its excellent melt fluidity, low molding temperature, and weak tendency to stick to molds. Th

2026/01/30 Injection Mold

-

Key Notes for PP Plastic Injection Molding Production

PP plastic is a general-purpose thermoplastic crystalline material with excellent fluidity and a wide plasticization temperature range, but it also features high shrinkage and brittleness at low tempe

2026/01/29 Plastic Injection Molding

-

Solutions for Insufficient Filling of Thin-Walled Parts in Plastic Molds

Thin-walled plastic mold parts refer to those with a regular wall thickness of no more than 1.5mm. Insufficient filling is a common defect in their injection molding, mainly caused by high melt flow r

2026/01/29 Plastic Molds

-

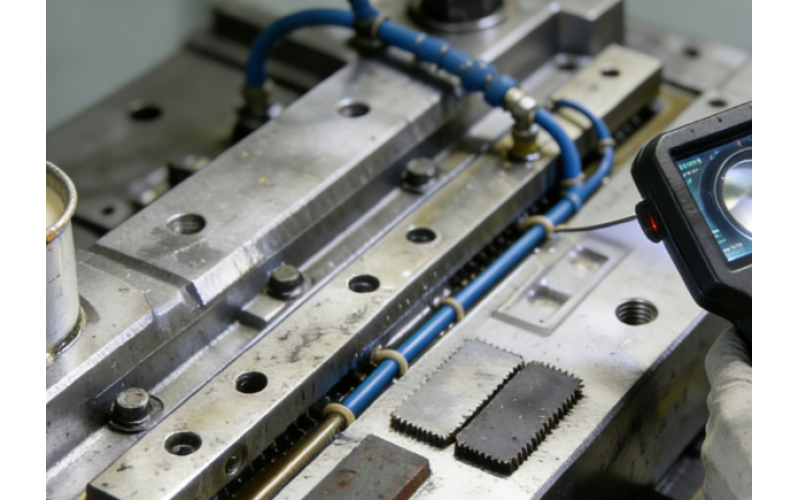

Leak Inspection and Sealing Repair for Plastic Molds

Cooling water channel leakage is a common fault in plastic mold injection production. Leaks cause mold rust, uneven mold temperature, and plastic part defects such as sink marks, deformation and weld

2026/01/29 Plastic Molds